Development of Eco-Friendly Construction Machines

Outline of the Research

Waste problems are now becoming unavoidable social problems. The technology that reduces the wastes and recycles them is an inevitable key technology for sustainable development and creation of a recycling society.

We are studying the development of construction machines that recycle the construction wastes, that is Eco-Friendly construction machines, and machine intelligence for zero emission at construction sites and mining sites.

Recent Research Topics

- (1) Theoretical and Experimental Studies on Agitation Torque of the Mobile Soil Recycling Machine

- (2) Effect of Soil Properties on the Performance of Mobile Soil Recycling Machine

- (3) Numerical Simulation of Excavated Soils and Additives in the Mobile Soil Recycling Machine

- (4) Numerical Simulation on Breaking Performance of Mobile Soil Recycling Machine for Clay-rich Cohesive Soil

- (5) Study on Separation Function of the Recycling Machine for Mixed Construction Wastes

(1) Theoretical and Experimental Studies on Agitation Torque of the Mobile Soil Recycling Machine

In order to recycle the excavated soils at the construction sites, they have to be modified by mixing the additives such as quicklime and cement. A mobile soil recycling machine is usually used at the construction sites to mix the soils and additives. In this case, it is very important to mix the soils and additives uniformly. Therefore, some researches have already carried out for the effect of mechanical parameters and soil properties on the mixing performance. However, the agitation torque of excavated soils and additives is not made clear as yet. Since the power which is equipped in the machine is limited, it often occurs that the excavated soils and additives are not well mixed and quality of the modified soils becomes extremely low if the large amount of excavated soils are fed into the machine at once. If the agitation torque based on the soil properties is obtained, it can be considered to determine the maximum feed volume of the soils into the machine with satisfying the uniform mixing of soils and additives. Furthermore, it enables the optimum design of the machine.

Therefore, we are studying the development of physical model to estimate the agitation torque and carrying out the experiments to confirm the validity of the model.

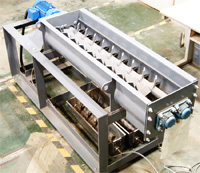

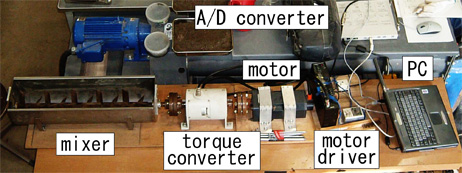

The experimental apparatus: This apparatus was made with imitating the actual soil recycling machine. This machine is now widely used in the construction sites to recycle the excavated soils and remediation of contaminated soils.

(2) Effect of Soil Properties on the Performance of Mobile Soil Recycling Machine

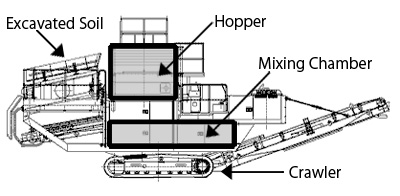

In the work by the soil recycling machine, the excavated soils are fed by the power shovel into the soil feeder and then delivered to the mixing chamber of the machine. The soils delivered to the mixing chamber was mixed with additives by the paddles, and then they are discharged by the belt conveyor. The processing volume of the soils by the paddle mixer was already investigated experimentally, but this value is strongly effected by the soil properties. If the large amount of soils which is over the mixing performance of the paddle mixer is fed into the mixing chamber, the soils are not well mixed by the paddle. In result, the quality of the modified soils becomes very low and at worst it causes the machine damage. That is, if the mixing performance can be obtained theoretically and the optimum operating conditions can be determined based on the soil properties and water content, the intelligent control of the machine can be expected.

Therefore, we are studying the relationship between the processing volume of the soils by the machine and agitation torque theoretically and experimentally to obtain the optimum operating conditions and to construct the intelligent control system.

Experimental Apparatus

If the large amount of soils are fed into the machine, it is sometimes difficult to carry out the effective mixing depending on the soil properties and water content as shown in the above figure.

(3) Numerical Simulation of Excavated Soils and Additives in the Mobile Soil Recycling Machine

The moisture and the viscosity of excavated soils produced in the construction site are usually rather high. Therefore, it is almost impossible to recycle the excavated soils produced from the construction site. In order to recycle the excavated soils, it is necessary to improve them at the soil-processing plant. Now, the excavated soils are transported by the dump truck to the soil processing plant and they are improved by adding the additives such as quicklime and cement. However, as the cost of transporting soils is very expensive, the excavated soils are often discarded illegally on the way to the plant.

Therefore, an soil-recycling machine has been receiving considerable attention recently. The mobile type soil-recycling machine is able to improve the soils by adding the additives at the construction site. However, not only the mechanical factors such as paddle inclination angle and paddle pitch but also the physical properties of the excavated soils affect the mixing performance of the excavated soils and additives. In this sense, experimental investigations are uneconomical and ineffective.

Therefore, we are trying to develop the numerical simulator by using DEM(Distinct Element Method) to analyze the mixing behavior of excavated soils and additives in the soil-recycling machine with dual shafts in order to assist the economical and effective design of the optimum soil- recycling machine.

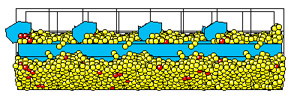

Outline of mobile soil-recycling machine

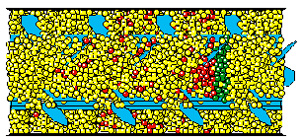

An example of simulation results : Yellow elements and red elements indicate the excavated soils and additives, respectively. Green elements indicate the additives supplied from the feeder. Blue parts indicate the paddle and shaft.

An example of simulation results

(4) Numerical Simulation on Breaking Performance of Mobile Soil Recycling Machine for Clay-rich Cohesive Soil

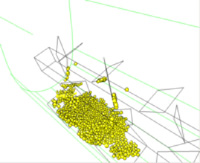

As mentioned before, we are trying to develop the numerical simulator by using DEM(Distinct Element Method) to analyze the mixing behavior of excavated soils and additives in the soil-recycling machine. Bu using this simulator, the breaking performance of massive soils is also investigated. In order to design the soil-recycling machine, it is necessary to understand the breaking performance for clay-rich cohesive soil, because this soil is easy to become massive and if the soil becomes massive, it is very hard to mix the soils and additives uniformly. In this case, experimental investigation needs much costs and long experimental period. If the simulation model is developed, the effective and economical design will be possible. In this study, the simulator to obtain the breaking performance was developed and simulated results were compared with the experimental ones.

An example of simulation results on breaking the cohesive soil massive

An example of soil fragments after breaking of 10 cm square soil massive by mobile soil recycling machine

(5) Study on Separation Function of the Recycling Machine for Mixed Construction Wastes

Several construction wastes are discharged from the demolishing work of buildings. Many recyclable materials such as square log, concrete and lumber are contained in the mixed construction wastes. If the several materials are mixed, they are wastes, but if they are separated, they will change into "resources". Therefore, separating demolishing is strongly recommended, but in the case of demolishing work of old houses, "minced demolishing", which demolishes the old house by the heavy machines without separating the materials. Consequently, there are several materials in the demolishing work sites, and separation task is carried out by hands. However, above task is dangerous because it has to be done besides the heavy machine and it takes a long time. Therefore, the recycling rate of the mixed construction wastes is still extremely low and illegal dumping of the construction wastes is a social problem. So, the development of the recycling machine of mixed construction wastes with having separation ability is desired.

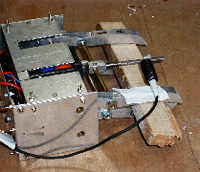

In this laboratory, we are carrying out the fundamental study on the separation ability of wood from other materials in order to develop the automatic separating machine of mixed construction wastes. Specifically, we are developing 1)image processing technique to detect the wooden part, 2)algorithm to measure the location of the wooden part, 3)holding method of the wooden part by machine hands, and 4)analyzing method of the hitting sounds to judge the material.

Mixed construction wastes recycling machine: This machine can separate the wood from other materials by using vision sensor and acoustic sensor.

Machine hand equipped the acoustic sensor (Microphone) : The materials are judged by analyzing the hitting sounds by the hammer.