Environmental Geomechatronics and Eco-Friendly Construction System

Outline of the Research

In a recovery construction work at disaster sites, unmanned construction has attracted attention in order to avoid the dangerous works. In realizing the unmanned construction, it is necessary to integrate mechanical engineering, geotechnical engineering and electrical organically. Therefore, Takahashi laboratory is carrying out the cooperative research on advanced Geomechatronics with other universities and institutes.

Recent Research Topics

- (1) Study on Task Planning for Autonomous Scooping of Crushed Rocks by an Intelligent Wheel Loader with a Stereo Vision System

- (2) Analysis of the Resistive Force acting on the Bucket of Power Shovel in the Excavating Task of Piled Fragment Rocks

- (3) Study on Development of non-Diffusive-Type Recovering Machine for High Water Content Mud

- (4) Development of Automatic Removal Machine for Sediment Rock Powder under Belt Conveyor

- (5) Study on the Mechanism of Over-Head-Type Load-Haul-Dump with a Vessel

- (6) Study on Automation of Rock Splitting Method

- (7) Study on Sideslip of Articulated Steering Wheeled Vehicle in Autonomous Locomotion

Future Researches

- (8) Environmental Geomechatronics

- (9) Local Production for Local Consumption of Construction Wastes

(1) Study on Task Planning for Autonomous Scooping of Crushed Rocks by an Intelligent Wheel Loader with a Stereo Vision System

In order to realize the autonomous scooping of the crushed rocks by the wheel loader, first of all, the loader has to recognize the shape of the rock pile and to plan the scooping task autonomously. Generally, scooping task is carried out by penetrating the bucket into the rock pile and lifting up the bucket to scoop the rocks. Therefore, in order to plan the scooping task, the scooping point and penetration direction of the bucket have to be determined. In this laboratory, we are studying the algorithm to determine the scooping point and penetration direction of the bucket based on the shape of the rock pile recognized by image processing. We are carrying out the scooping experiments by using the wheel loader model with a stereo vision system. In these experiments, the wheel loader recognizes the rock pile and determines the scooping point and penetration direction of the bucket. Then, it moves to the scooping point and penetrates the bucket into the rock pile, and scoops the rocks. We have already confirmed that the working efficiency by using the algorithm proposed in this laboratory was much higher than that by the teaching playback.

Intelligent wheel loader : This loader constructs the effective scooping task plan based on the vision system on the machine and moves autonomously.

(2) Analysis of the Resistive Force acting on the Bucket of Power Shovel in the Excavating Task of Piled Fragment Rocks

When the autonomous excavating task of soils and rocks is carried out by using the power shovel, estimation of the working situation is very important to ensure the safety. In order to estimate the working situation, it can be considered that the utilization of the force sensor is indispensable. That is, the machine has to judge the followings automatically:

- (1)Whether the work is progressing smoothly or not

- (2)Whether the bucket is filled with soils/rocks or not

- (3)Whether the tip of the bucket hits the boulder or not

- (4)Whether the machine is in the dangerous situation or not

In order to judge the above situations, it is necessary to obtain the theoretical resistive forces acting on the bucket when the excavating task is going smoothly, and to compare the theoretical resistive forces and measured ones by the force sensor attached on the machine.

Therefore, we are studying to derive the theoretical model to estimate the resistive force acting on the bucket of the power shovel and wheel loader. Furthermore, resistive forces are measured by using a small model of the power shovel, and measured values are compared with the theoretical ones to confirm the validity of the derived theoretical model.

Intelligent power shovel : This machine will be used in the disaster-relief work and lunar excavation mission.

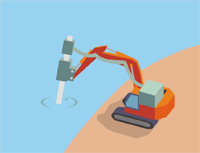

(3) Study on Development of non-Diffusive-Type Recovering Machine for High Water Content Mud

Recently, much sewage effluent flow into the rivers, lakes and ponds. Consequently, they are eutrophicated, and much sludge is generating. As the sludge causes the decrease of the dam capacity, blockage of the drainage canal, deterioration of life environment due to the bad smell and declining quality of water, it is imperative to establish the effective removal system of the sludge.

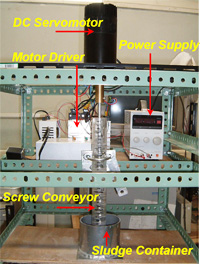

In this study, the screw conveyor was used to develop the removal machine of the sludge. In this experiment, the conveying performance and non-diffusivity were estimated. It was found that the effect of the rotation number on the conveying performance was significant. Furthermore, it was confirmed that that the conveying performance of large screw diameter machine is greater that that of small screw diameter machine.

It is well-known that turbidity of the water is related to the SS(Suspended Solids). Therefore, in this experiment, the transmission of light in the water after the sludge removal was measured in order to estimate the non-diffusivity while removing the sludge. It was found through the comparison between the results of bucket removal and those of screw conveyor removal that diffusivity by the screw conveyor is much smaller than that by the bucket.

Image of non-diffusive recovering system for high water content mud

Outline of experimental apparatus

(4) Development of Automatic Removal Machine for Sediment Rock Powder under Belt Conveyor

A belt conveyor is an useful equipment to carry the crushed ores and soils, and is used widely in mining and civil works. However, there is a problem that the rock powders attached on the surface of the belt fall down and sediment on the floor when the belt returns. Now, the sediment rock powder is removed by the workers. However, an accident that the worker was caught by the belt is reported during the removal work of sediments.

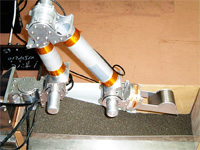

Therefore, we are developing an automatic removal machine for sediment rock powders that can move in a narrow space such as the one under the belt conveyor. The figure below shows the automatic removal machine developed in Takahashi Laboratory, and the validity of this machine was confirmed through the experiments.

Sediment rock powders under the belt conveyor

Automatic removal machine for sediment rock powders under the belt conveyor

(5) Study on the Mechanism of Over-Head-Type Load-Haul-Dump with a Vessel

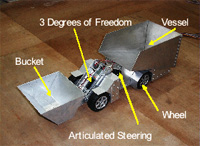

In this study, an over-head-type Load- Haul-Dump (LHD) with a vessel (Advanced LHD with a Vessel: ALV) is proposed to increase the carrying capacity. As the working environment is severe for workers, especially in underground mines, unmanned LHD task is desirable. In this case, the cabin for the operator is not necessary. Therefore, overhead loading into the vessel will be possible.

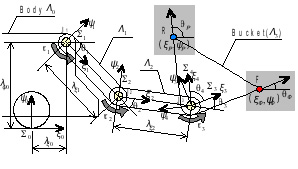

We are proposing a concept of ALV. In this study, kinematics and dynamics of ALV is now investigated. Furthermore, the experimental results by using the ALV model are also carried out. In order to obtain the mobility of ALV, the wheels and the articulated steering system are adopted for moving and steering. Furthermore, in order to increase the carrying capacity, a vessel is installed on the rear body. Until now, we have confirmed through the experiments that the working efficiency of ALV is higher than that of traditional LHD.

Over-Head-Type Load- Haul-Dump

(Advanced Loader with a Vessel : ALV)

Modeling of ALV

(6) Study on Automation of Rock Splitting Method

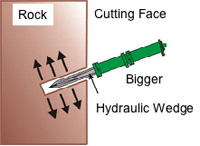

Recently, the rock splitting method is often used to construct the tunnel because the blasting method is restricted in the construction site near city area suburbs. However, the working efficiency of the rock splitting method is extremely low. Therefore, the automation of rock splitting method has been receiving considerable attention to increase the working efficiency. This study is concerned with the automation of rock splitting method for tunnel construction. In order to automate the rock splitting, the following tasks are necessary:

- 1) Automatic recognition of holes drilled on the cutting face

- 2) Automatic control to make the tip of the bigger move to the recognized holes

- 3) Automatic insert of the bigger into the drilled hole

In this study, the image processing procedure was proposed by using CCD camera and laser pointer in order to recognize the location of the holes drilled on the uneven cutting surface. Furthermore, the algorithm to insert the bigger automatically into the drilled holes by using the strain gauges attached on the bigger. It was confirmed through the model experiment that this algorithm worked well. If the hole is drilled vertically to the cutting face, it took 1 minute to complete the insert of the bigger. However, if the hole is not drilled vertically to the cutting face, it took 12 minutes to complete the insert of the bigger, and this time is much larger than that in the case that the hole is drilled vertically. Therefore, it was confirmed that the holes should be drilled vertically to the cutting face to increase the working efficiency by rock splitting method.

Concept of rock breaking by bigger

The experiment to automatic rock breaking: The bigger is controlled automatically so that the bigger is inserted into the drilled hole.

(7) Study on Sideslip of Articulated Steering Wheeled Vehicle in Autonomous Locomotion

The driving mechanism of mobile machines are classified into crawler type and wheel type. Especially, when the mobility is more important, the wheel type is adopted. One of the features of wheel type mobile machines is articulate steering system. The machine consists of two units, that is front unit and rear unit, and these unit are connected at center pin. The vehicle of articulate steering system has an advantage that the mobility is very high because the turning radius is small, and trafficability is very high because the rear wheel moves along the same trajectory of the front wheel. On the other hand, sideslip occurs easily in turning. This sideslip will be a big problem to realize the autonomous locomotion of the vehicle of articulate steering system.

Some researches on autonomous control based on the kinematics assuming no sideslip are carried out already. However, there are few researches with taking into account the sideslip. Therefore, we are studying the autonomous control based on the kinematics with considering the sideslip. We are studying the control algorithm to return to the original moving path when the vehicle goes out from the moving path by sideslip in turning.

Articulate steering wheeled vehicle developed in Takahashi Laboratory

The experiments of autonomous movement of articulate steering wheeled vehicle

(8) Environmental Geomechatronics

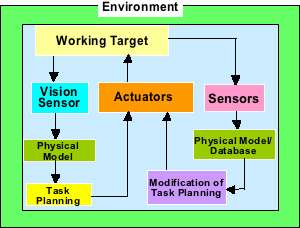

No construction with neglecting the environmental burden will be done in the future construction. That is, sustainable mechanical construction system will be strongly desired. Therefore, we are proposing the "Geomechatronics" with considering the environment, that is, "Environmental Geomechatronics", and are studying the key technologies on "Environmental Geomechatronics". The concept of "Environmental Geomechatronics" is as follows: When the machine makes the working plan by itself, it makes a trajectory of movement so that the environmental burden becomes minimum. Consequently, the fuel consumption reduces and the emission of greenhouse gases (i.e. CO2) will be reduced.

As shown in the figure below, in Geomechatronics, the most effective working plan is generated after the machine recognizes the working environment. However, in Environmental Geomehcatronics, the construction method of minimum fuel consumption and minimum emission of greenhouse gases, the most smooth trajectory of machine movement, ground properties etc. are considered. Not only the efficiency but also the environmental burden are considered in "Environmental Geomechatronics". That is, the concept of "Environmental Geomechatronics" is as follows: The machine recognizes the ground properties and situation by itself using several intelligent sensors. Then, the machine makes a working plan and trajectories of minimum fuel consumption and minimum emission of greenhouse gases based on the sensing information. Finally, the machine is controlled automatically and effectively to follow the task plan which is made with considering the efficiency and environment.

Image of Environmental Geomechatronics

(9) Local Production for Local Consumption of Construction Wastes

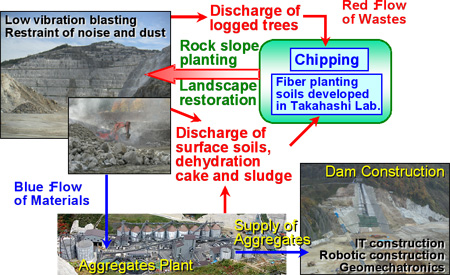

In order to conduct the mechanical construction in harmony with environment, the wastes discharged from the construction sites should be processed and recycled in the construction sites, not carrying outside of the construction sites. This is a kind of "Local Production for Local Consumption" of construction wastes. For example, as shown in the figure, a large amount of soils, crushed stones and aggregates are necessary at the dam construction site. If these materials are obtained from near mountains, the woods have to be cut down and surface soils have to be excavated. In result, much logged trees and excavated soils are discharged. In order to conduct the mechanical construction in harmony with environment, it is necessary to utilize these wastes efficiently and to restore the surrounding environment. The crushed stones obtained at the mountains are transported to the crushing plant or aggregate plant, and aggregates are produced. These aggregates are used to construct the dam, but at the same time, a large amount of dehydration cake and high water content mud are discharged. Takahashi Laboratory is developing a new resource circulating/recycling system of construction wastes. In this system, the soil wastes are recycled to the planting soils with fiber and the logged trees are chipped and then chips are mixed with the planting soils with fiber. As it is already confirmed that planting soils with fiber and chips are the best for rock slope greening. We are thinking that if above resource circulation/recycling system is established, "Local Production for Local Consumption" of construction wastes will be possible and this system will contribute the landscape restoration.

An example of "Local Production for Local Consumption" of construction wastes